| Ultrasonic Vibration Micro Nozzle |

|

The Ultrasonic Vibration Micro Nozzle transducer is constructed using a piezoelectric ceramic material and metal foil, on which thousands of micro nozzles are formed. Using the same principle as an inkjet printer, this transducer atomizes water or liquids through a matrix of microscopic holes about 7-10 £g m. in diameter. This ultrasonic transducer uses the siphon principle to draw small amounts of liquid to the surface of metal foil and then atomizes the liquid more efficiency than conventional ultrasonic atomizing transducers. In conventional ultrasonic systems, a high liquid level must be maintained in the tank to cover the surface of the ultrasonic atomizing transducer. |

| Features: | Applications: |

|

|

| Specification | ||

| Model Number | M2313500 | |

| Resonant Frequency | 143.0¡Ó5KHz | |

| Impedance | 10 Ohm typ. | |

| Capacitance | 2300¡Ó20% pF | |

| Dimensions | L: | 29.1±0.2 mm |

| W: | 17.3±0.1 mm | |

| T: | 1.0±0.1 mm (PZT Element) | |

| Metal Material | 50 μm (Ni- Co Alloy) | |

| Nozzle size | 7±3 £g m | |

| Impedance/Phase Angle | ||

|

||

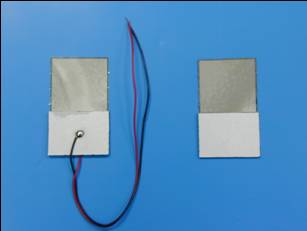

| Mounting Pads ( Pads material: Silicone Rubber or other elastic resins) | ||

| ||

| Top | ||

| Driving Circuit | ||

| ||

| Remark: The negative side faces to the opening, the positive side faces to the liquid source, if driving circuit uses NPN transistor. | ||

Top